1.Introduction

There is a national skills shortage in the global composites sector, so raising awareness of science and engineering of composite materials to the wider community is important to produce future talent. The Fibre Reinforced Composites Engineering module will use our own research experiences to ensure the lecture content is current and industrially relevant, raising awareness of composite materials to younger members of the academic community. One of the text books for this course ('Design and Manufacture of Structural Composites') is recently completed editing by the module convenors, which outlines the manufacturing challenges associated with fibre reinforced polymers for high-performance applications. The book includes contributions from leading experts in the field and provides an essential reference resource for members of industry, materials researchers, science and engineering students and educators who are working in the field of polymer matrix composites.

2.How to apply?

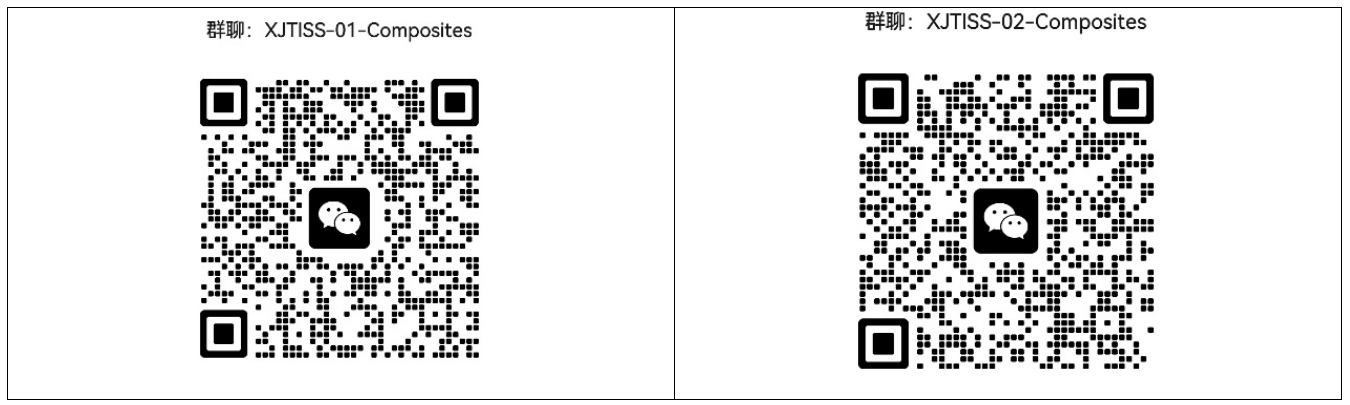

Anyone who is interested in attending online class, please scan the follow QR code to join the Wechat Group.

If you have any questions, please feel free to contact us through the following email address: Shuai.Chen@xjtu.edu.cn

3.Learning outcomes

(1)To gain an awareness of the potential of fibre reinforced composites in engineering applications

(2)To appreciate the range of constituent materials and the variety of processing routes available

(3)To appreciate the relationships between design, processing and mechanical properties

(4)To gain an elementary understanding of the mechanics of anisotropic materials

(5)To appreciate the design methods which are available for composite materials

4.Module convenors

·Domestic convenor: Professor Shuai Chen

Professor Shuai Chen is a professor at International Centre for Machinery, School of Mechanical Engineering, Xi’an Jiaotong University. During the past 15 years, Shuai has specialised in composites manufacturing research, which has made significant impacts on reducing the process complexity, manufacturing costs and production cycle timefor industry uptake.His current research focuses on design, analysis, and optimisation of composites forming process for aeronautical, aerospace and automotive sectors. He has specialised in the development of composites manufacturing processes and simulations, and is committed to supplying feasible solutions for high-quality and defect-free preforms by material/process optimisation.

·International convenor: Professor Lee Harper

Professor Lee Harper is arecently promoted professor at the University of Nottingham, where his research for the past 20 years has focussed on material and process developments for fibre reinforced polymer composites. He is currently the manager of the EPSRC Future Composites Manufacturing Research Hub, which is the largest single investment for fundamental research (TRL1-3) in composites manufacturing in the UK. Lee manages a funding portfolio of over £10m, working directly with 15 UK universities, 4 High Value Manufacturing Catapult centres and 43 industrial partners. He is a member of the Composites Leadership Forum's Technology Working Group, responsible for delivery of the UK Composites strategy, reporting to the Department for Business, Energy and Industrial Strategy (BEIS). Professor Harper is also an active member of the Society for the Advancement of Material and Process Engineering, chairing the Young Engineer and Student (YES) committee, which promotes collaboration, provides social engagement and shares expertise with the next generation of leaders within the composites sector.

5.Lecture topics

The module is going to deliver fundamental knowledges about fibre reinforce composites manufacturing, which is suitable for both undergraduate and postgraduate students. This module includes 8 lectures and each one lasts for 1.5-2 hours. Its contents have been preliminary planned as below:

Lecture 1: Introduction to composite materials

Lecture 2: Constituent materials

Lecture 3: Intermediate processes

Lecture 4: Preforming processes

Lecture 5: Polymer Processing + Moulding 1

Lecture 6: Moulding 2 + Post-moulding

Lecture 7: Design and validation

Lecture 8: Recycling and sustainability

Please note that the lecture plan may be subject to changes. And any changes will be notified through the course’s WeChat group. We do suggest regularly check the course updates during the period.

6.Import information

The lectures will be arranged during 20-25 July 2025, which is subject to international convenor’s agenda. Once the timetable is confirmed, the details will be announced in the WeChat group later.